A Loop System For a Producer Of Bathroom Furnishing

Group Nivelles, based in Gingelom, specializes in producing bathroom furnishings such as stone and artificial showers, sinks, and drainage channels. Ensuring efficient manufacturing and distribution of these materials requires an optimal product flow, which is where we excel. Together with our client, we found the perfect solution to optimize their product flow.

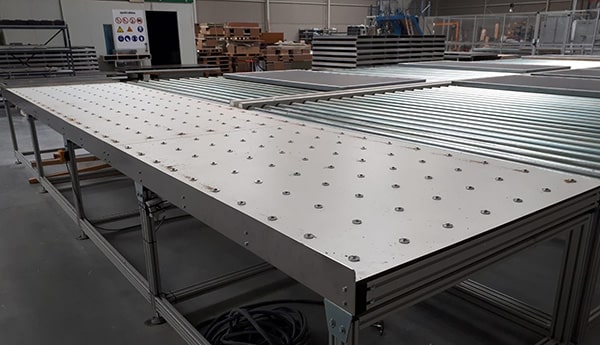

We implemented an efficient continuous loop system for the production of plastic panels. Roller conveyors transport empty molds to a flat belt conveyor, with adjusted speed to ensure accurate filling. The conveyor systems are custom-made to handle the wide materials. After filling, the molds need to be cured in a buffer zone. Transfer devices ensure the panels return from the flat belt conveyor to the roller conveyor.

The cured panels are automatically transferred to a ball table for easy removal. The empty molds are returned to the circuit for reuse. In addition to efficiency, safety in the production environment was also a priority. Enclosures around the conveyors and molding machine meet the client’s specific safety requirements.

Product type: Roller Conveyors

Extra info: Ball table with roller conveyor for transporting panels

Sector: Production & packaging