Internal Logistics Optimization at Besli: Less Walking, More Picking

Besli, a Dutch wholesaler of electronic materials based in Arnhem, needed the perfect solution to optimize their internal logistics, and pick orders faster and more efficiently in their warehouse. We provided the ideal solution.

From the outset, Besli’s goal was clear: reduce the walking distances of their employees and increase order picking within the same timeframe. A future transport system is needed to make them work more efficiently and enhance the internal logistics of their warehouse.

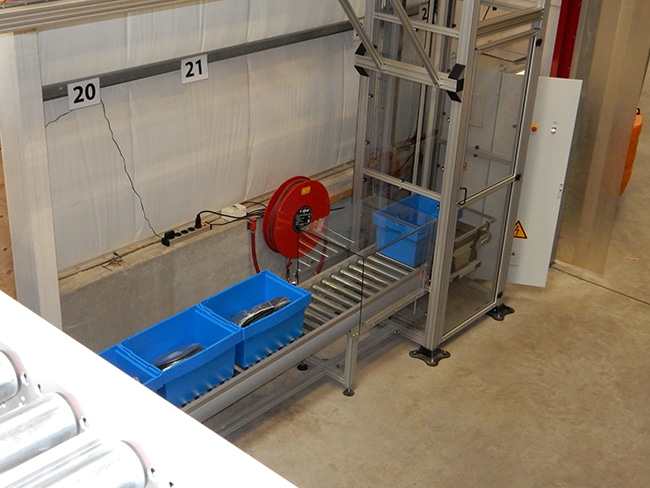

The bins where pickers gather their orders now depart from a mezzanine floor. Forklifts transport the bins through an aisle to the other side. Subsequently, the bins are transported vertically downward and rolled out onto a gravity roller conveyor.

We also improved internal logistics by installing a conveyor belt at the packing tables. Employees place their packed orders on these belts, which then depart to a central point where all materials are collected onto carts.

Product type: Roller Conveyors

Extra info: Lift

Sector: Production & packaging